Alfa Industries

One mission… One team… One goal…

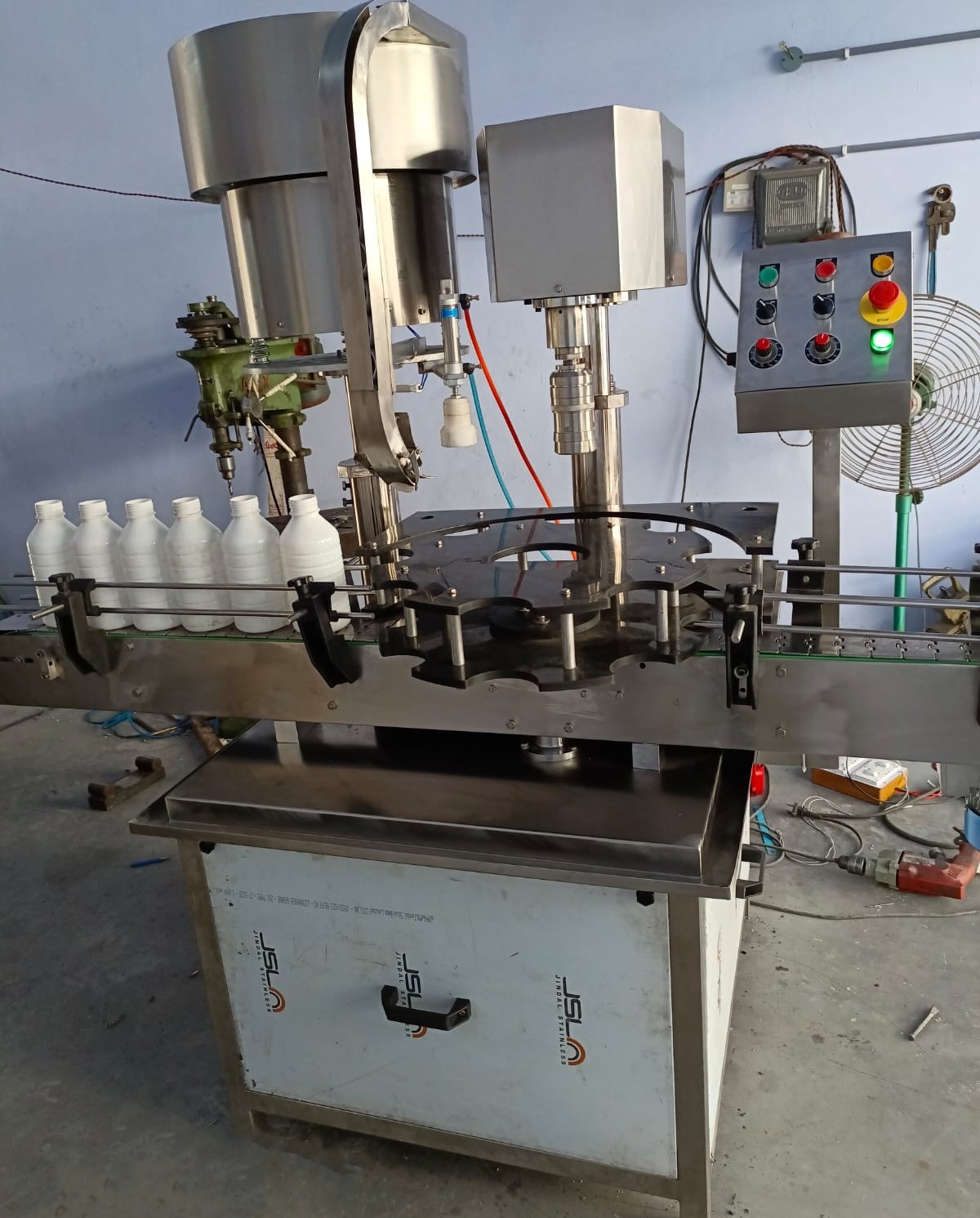

Automatic Sunflower Oil Filling Machine

An Automatic Sunflower Oil Filling Machine is a specialized piece of equipment designed to accurately and efficiently fill bottles or containers with sunflower oil. This machinery is widely used in the edible oil industry to ensure precise filling, reduce wastage, and maintain product quality. Automatic filling machines streamline the production process, enhance productivity, and are crucial for maintaining hygiene and consistency in sunflower oil packaging.

- Machine Type: Inline or Rotary Filling Machine

- Material: Stainless Steel (SS304/SS316)

- Capacity: 700 to 2000 bottles per hour (varies by model)

- Filling Volume Range: 50ml to 5 liters

- Bottle Diameter Range: 30mm to 120mm

- Bottle Height Range: 50mm to 300mm

- Filling Accuracy: ±0.2%

- Nozzle Type: Anti-drip, diving, or fixed nozzles

- Power Supply: 220V/380V, 50/60Hz

- Control System: PLC (Programmable Logic Controller)

- Operator Interface: Touchscreen HMI (Human-Machine Interface)

- Air Pressure: 0.4-0.6 MPa

- Dimensions: Varies by model, typically around 1000mm x 1200mm x 1300mm

- Weight: Approx. 300-400 kg depending on the model

Construction:

- High-quality stainless steel construction for durability and hygiene.

- Modular design for easy integration and scalability.

Filling Mechanism:

- Utilizes volumetric, gravimetric, or Servo-based filling techniques for precision.

- Anti-drip nozzles to prevent spillage and ensure clean operation.

- Automatic bottle positioning and height adjustment for various container sizes.

Control and Automation:

- Advanced PLC system for precise control and easy adjustments.

- Touchscreen HMI for user-friendly operation and real-time monitoring.

- Automated bottle detection and rejection system for quality control.

Safety Features:

- Emergency stop buttons.

- Safety guards and interlocks.

- Overload protection for motors and pumps.

Maintenance and Support:

- Easy access to components for cleaning and maintenance.

- Remote diagnostics and support capabilities.

- Comprehensive user manual and training provided.

The future of Automatic Sunflower Oil Filling Machines is geared towards greater automation, efficiency, and integration with advanced technologies. Key trends and advancements include:

IoT Integration:

- Real-time monitoring and data analytics for predictive maintenance and operational optimization.

- Cloud connectivity for remote management and troubleshooting.

Artificial Intelligence:

- Machine learning algorithms for adaptive control and error minimization.

- Enhanced vision systems with AI for improved quality control and defect detection.

Sustainability:

- Development of energy-efficient models to lower power consumption.

- Use of environmentally friendly materials and designs to reduce carbon footprint.

Customization and Flexibility:

- Increased demand for machines capable of handling various bottle shapes and sizes with minimal changeover time.

- Enhanced flexibility to accommodate small batch production and rapid product changes.

Advanced Safety and Hygiene:

- Enhanced compliance with global safety and hygiene standards, particularly in the food industry.

- Innovations in design to minimize contamination risks and simplify cleaning processes.

Investing in the latest automatic sunflower oil filling machines allows businesses to stay competitive, ensuring efficient, reliable, and scalable production processes that meet evolving market demands.

Product Category: