Alfa Industries

Complete range Of Packing Solutions.

TRENDING

Automatic oil filling machine

The demand for automatic oil-filling machines in India has significantly increased due to the country's expanding industrial sector. Indian manufacturers and suppliers now offer state-of-the-art oil-filling machines that cater to various applications, from edible oil bottling to automotive lubricants. These machines are designed to meet the specific needs of the Indian market, ensuring efficiency, accuracy, and cost-effectiveness. Whether for small-scale operations or large industrial plants, automatic oil-filling machines in India are engineered to enhance productivity and maintain high quality standards.

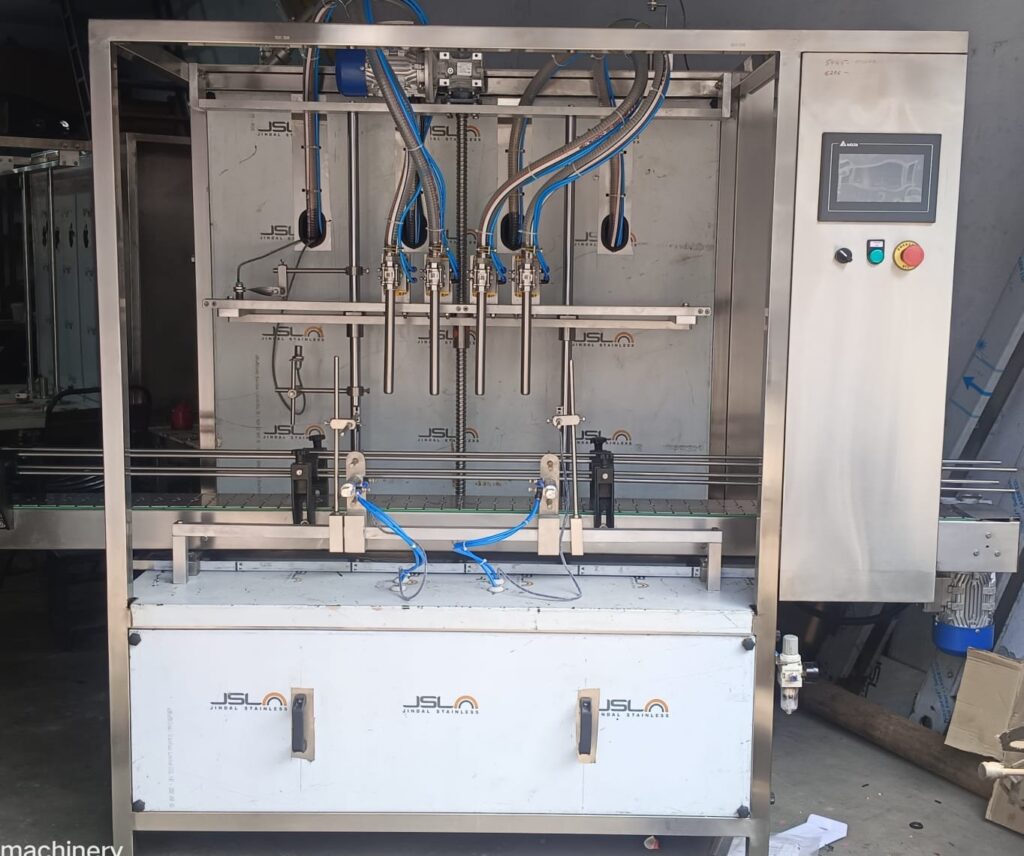

Automatic oil filling machine

An automatic oil-filling machine is an advanced piece of equipment designed for the efficient and precise filling of various types of oils into containers. These machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and automotive to streamline the bottling process, reduce waste, and ensure consistent product quality. The machine typically features a conveyor system, filling nozzles, a control panel, and sensors to automate the entire filling process. The nozzles are designed to handle different viscosities and volumes, ensuring versatility across a range of oil products.

- Filling Range: 50ml to 5000ml (customizable)

- Filling Speed: Up to 60 bottles per minute (depending on bottle size and oil viscosity)

- Accuracy: ±0.2%

- Nozzle Type: Anti-drip, multiple nozzles available (2, 4, 6, 8, 12, etc.)

- Control System: PLC (Programmable Logic Controller) with touch screen interface

- Power Supply: 220V/380V, 50Hz/60Hz

- Compressed Air Requirement: 0.4-0.6MPa

- Material: Stainless steel (304/316L for contact parts)

- Dimensions: Customized based on production line requirements

- Weight: Approx. 500 kg

- Additional Features: Automatic bottle feeding and discharge, level sensor for hopper, safety interlocks, and emergency stop button.

- High Efficiency: Capable of filling a high volume of bottles per minute, significantly increasing production rates.

- Precision Filling: Advanced sensors and PLC control ensure accurate filling, reducing waste and ensuring product consistency.

- Versatility: Adjustable settings to accommodate various oil types and bottle sizes, making it suitable for different industries.

- User-Friendly Interface: Touch screen controls for easy operation and quick adjustments.

- Durability: Constructed from high-quality stainless steel, ensuring longevity and resistance to corrosion.

- Safety: Equipped with safety interlocks and emergency stop functions to protect operators and prevent accidents.

- Easy Maintenance: Designed for easy cleaning and maintenance, with quick-disconnect parts for hassle-free upkeep.

- Food and Beverage Industry: Filling edible oils such as olive oil, sunflower oil, and vegetable oil.

- Pharmaceutical Industry: Bottling medicinal oils and dietary supplements.

- Cosmetic Industry: Filling beauty and skincare oils.

- Automotive Industry: Dispensing lubricants and motor oils.

- Chemical Industry: Packaging industrial oils and other viscous liquids.

Product Category: